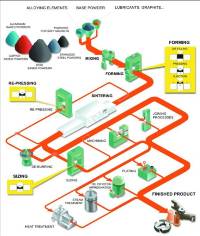

From the basic processes, different complementary operations are given in order to perfect these sintered parts. They are usually subject to additional processes such as sizing, joining processes and machining, these are the most prominent, in order to achieve narrower tolerances and specific properties for particular applications, properties that can not be achieved through the basic cycle.

SIZING

It consists of compacting again the part inside a rigid mould which has the symmetrical opposite shape of the part.

Sizing can have several purposes:

– Increasing the dimensional precision in diameter, reaching up to IT 5. The densification degree is lower than 4%.

– Creating relief geometrical details not feasible in the compacted part, or improving roughness.

– Densification. The applied densification degree is 7-10%, and it is also known as Coining.

DEBURRING

Deburring is applied to remove burrs inherent to compacting process. Burrs are removed either in bulk (tumbling, shot blasting, …), or on a unit basis (brushing, polishing, electrolytic deburring, …). Bulk deburring is sometimes used to provide an homogeneous surface aspect, or a very low roughness.

MACHINING

Sintered components can be sometimes machined when a shape or tolerance not achievable by compacting is required. Sintered parts support all conventional machining operations, ie., turning, milling, drilling, threading, grinding, lapping, reaming, polishing, and so forth.

CLEANING

Cleaning operations are used to reduce or eliminate the amount of pollutants, solid or liquid, that a part may contain. There are many techniques, depending on material, type of pollutant, and required specifications.

STEAM TREATMENT

This is a thermal cycle of controlled oxidation of a steel, carried out in continuous furnaces with water steam. A magnetite layer coat is formed on the part surface and porosity. Its application on a component increases its compression strength, seals its porosity, and improves its environmental corrosion resistance.

HEAT TREATMENT

A heat treatment is a thermal cycle that modifies the material properties. They are typically applied to increase hardness and strength of the component. The main surface or core heat treatments are: quenching, case hardening, and carbonitriding. Induction hardening is used to increase hardness in a local area of the part.

A particular case are the sinter-hardened components, which are made of a special type of steel that becomes hardened in the sintering furnace during the cooling.

BUSHING ASSEMBLY

The cap is placed in the piece once it has been through the previous processes. The cap increases the resistance of the final piece.

TEFLON COATING

It is a contribution of Polytetrafluoroethylene, better known as Teflon, on the surface of the component, which modifies the surface properties without changing the chemical composition of the metallic base. It is applied with the intention of reducing the wear and friction of the piece, protecting it against corrosion.

VISUAL INSPECTION

Once the pieces pass the previous processes, they pass to the penultimate productive phase, the visual inspection. In this process is where the piece is analyzed in search of a defect. We have three machines of last generation in visual inspection, and 5 workers working in the same function. This is due to the high manufacturing pace we have been in recent years.

The work of the machine of visual inspection is simple, through laser, if the machine detects any imperfection in the piece discards it and does not let it follow the process of the correct pieces.

COATING

It is a material deposition on the component surface, which modifies the surface properties without changing the base metal chemical composition. Coatings are applied to fulfil functions under fatigue, wear, friction, or corrosion protection.

Sintered parts accept almost all conventional coatings, like zinc plating, chromium plating, nickel plating and phosphating.

PACKAGING

Discarded defective parts are packed in boxes with the MFS logo. This process, like the previous one, is done automatically and manually. The packing machine receives the boxes and automatically places the pieces.